From Earth to Moon: The Quest for Rare Earth Minerals

Our smartphones, electric car batteries, and renewable energy systems all depend on rare earth minerals – but Earth’s supplies are running dangerously low. This guide is for entrepreneurs, investors, and tech enthusiasts who want to understand how space mining technology could solve our rare earth shortage solutions and reshape global economics.

We face a growing crisis. Traditional mining creates massive environmental damage while countries compete for control of remaining rare earth elements applications. The answer might lie 240,000 miles above us, where lunar rare earth deposits could provide centuries worth of materials without destroying ecosystems.

We’ll explore how breakthrough space resource extraction technologies are making moon mining feasibility a reality, not science fiction. You’ll discover the economic powerhouse that lunar mining represents and learn about the technical challenges engineers are solving right now. We’ll also cover how asteroid mining fits into this new space economy and what regulatory frameworks need to change before the first lunar mining operation launches.

The race to space isn’t just about exploration anymore – it’s about securing the materials that power our modern world.

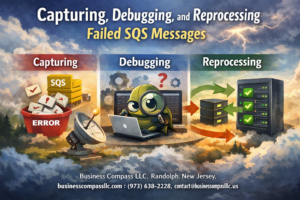

Understanding Rare Earth Minerals and Their Critical Applications

Essential elements powering modern technology and green energy

Rare earth minerals form the backbone of virtually every piece of modern technology you interact with daily. Your smartphone contains at least 16 different rare earth elements, from neodymium in the speakers to terbium in the display screen. These 17 chemical elements, despite their name, aren’t actually rare in terms of abundance – they’re called “rare” because they rarely occur in concentrated, economically extractable deposits.

The green energy revolution depends heavily on these materials. Wind turbines require massive amounts of neodymium and dysprosium for their permanent magnets, while electric vehicle batteries rely on lithium, cobalt, and various rare earth elements for optimal performance. Solar panels incorporate indium, gallium, and tellurium to convert sunlight into electricity efficiently.

| Application | Key Rare Earth Elements | Critical Function |

|---|---|---|

| Wind Turbines | Neodymium, Dysprosium | Permanent magnets for generators |

| Electric Vehicles | Lithium, Cobalt, Lanthanum | Battery performance and motors |

| Solar Panels | Indium, Gallium, Tellurium | Photovoltaic conversion |

| LED Lighting | Europium, Terbium, Yttrium | Color production and efficiency |

Strategic importance in defense and aerospace industries

Defense systems worldwide depend on rare earth elements for their most advanced capabilities. Precision-guided missiles use samarium-cobalt magnets that maintain performance in extreme temperatures. Night vision goggles rely on lanthanum for their optical systems, while radar and sonar equipment require various rare earth compounds for signal processing.

The aerospace industry can’t function without these materials. Jet engines incorporate rare earth elements in their superalloys to withstand extreme heat and stress. Satellite communication systems use rare earth-doped fiber optics, and GPS technology depends on atomic clocks that require specific rare earth compounds for precision timing.

F-35 fighter jets contain approximately 920 pounds of rare earth materials, while a single Virginia-class submarine requires about 9,200 pounds. This massive consumption creates strategic vulnerabilities when supply chains face disruption.

Supply chain vulnerabilities threatening global innovation

China currently controls roughly 80% of global rare earth processing capacity, creating a chokepoint that threatens technological advancement worldwide. This concentration isn’t just about mining – it extends to the complex refining and processing stages that transform raw ore into usable materials.

The problem runs deeper than geographic concentration. Rare earth processing involves environmentally challenging procedures that many countries avoid due to strict environmental regulations. China’s willingness to accept these environmental costs has allowed them to dominate the market, but this creates dangerous dependencies for other nations.

Recent trade tensions have highlighted these vulnerabilities. Price volatility and supply disruptions can halt production lines for everything from smartphones to military equipment. Companies are scrambling to diversify their supply chains, but building new processing facilities takes years and requires substantial investment.

The automotive industry faces particular challenges as electric vehicle production ramps up. Tesla and other manufacturers have experienced delays and cost increases due to rare earth supply constraints, pushing companies to explore alternative technologies and seek new sources – including the promising frontier of space-based mining.

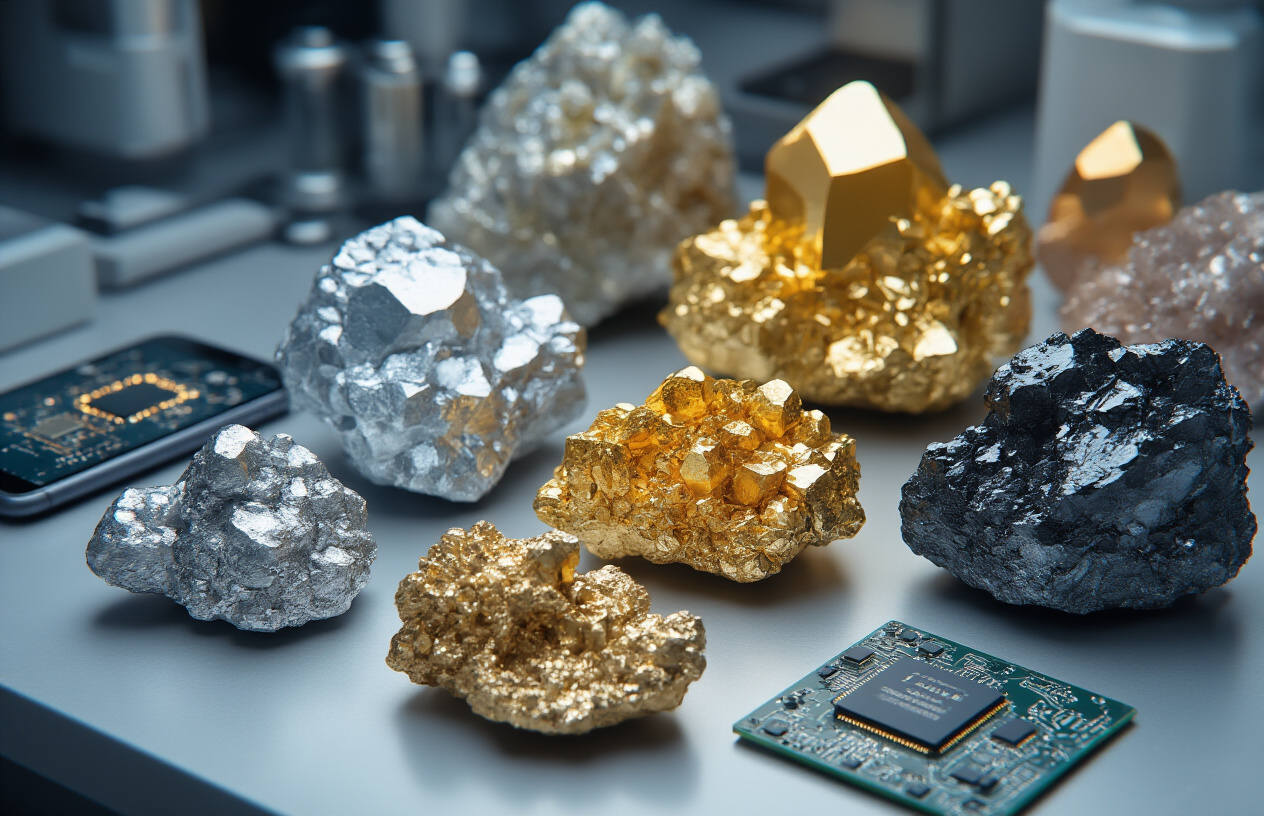

Earth’s Declining Reserves and Environmental Challenges

Finite deposits reaching depletion in key mining regions

The world’s largest rare earth mineral deposits are running out faster than anyone anticipated. China, which controls roughly 60% of global rare earth production, has already closed several major mines due to resource exhaustion. The Bayan Obo mine in Inner Mongolia, once considered inexhaustible, now shows clear signs of depletion with ore grades dropping significantly over the past decade.

Mountain Pass in California, America’s primary rare earth source, faces similar challenges. After decades of extraction, the easily accessible high-grade deposits are nearly gone, forcing miners to dig deeper and process lower-quality ore. This pattern repeats across mining regions in Australia, Brazil, and India, where geologists estimate remaining economically viable reserves could last only 15-25 years at current consumption rates.

The situation becomes more alarming when you consider that rare earth elements applications are expanding rapidly. Electric vehicles, wind turbines, and advanced electronics all depend heavily on these materials, creating unprecedented demand growth that outpaces new discovery rates.

Devastating environmental impact of traditional extraction methods

Traditional rare earth extraction leaves behind an environmental disaster that takes generations to heal. For every ton of rare earth elements produced, miners generate approximately 2,000 tons of toxic waste containing radioactive thorium and uranium byproducts.

The Baotou region in China exemplifies this destruction. Once-fertile farmland now resembles a moonscape, with artificial lakes filled with black, radioactive sludge stretching for miles. Local residents report increased cancer rates, birth defects, and respiratory illnesses directly linked to mining operations. Groundwater contamination has spread far beyond mining sites, affecting millions of people downstream.

Processing facilities require massive amounts of water and harsh chemicals including sulfuric acid, hydrochloric acid, and sodium hydroxide. These chemicals leach into soil and waterways, creating dead zones where nothing can survive. A single facility processing rare earth minerals can contaminate hundreds of square kilometers of surrounding ecosystem.

Air pollution from rare earth mining includes radioactive dust particles and toxic gases that drift across international borders. Communities hundreds of kilometers away from mining sites report elevated levels of heavy metals in their soil and water supplies.

Geopolitical tensions controlling access to critical supplies

China’s dominance over rare earth shortage solutions has created a weapon of economic warfare that threatens global stability. When trade tensions escalated with Japan in 2010, China temporarily halted rare earth exports, sending prices skyrocketing by 3,000% within months. This single event demonstrated how easily one nation could paralyze entire industries worldwide.

The situation has only intensified as technological competition grows between superpowers. China has repeatedly used export restrictions as diplomatic leverage, forcing companies to relocate manufacturing operations or abandon projects entirely. European automakers faced production delays worth billions when Chinese suppliers suddenly reduced shipments during recent trade disputes.

Military applications make this control even more concerning. Advanced missile guidance systems, radar equipment, and fighter jet components all require specific rare earth elements that China could restrict at will. Defense contractors across NATO countries scramble to secure alternative sources, often paying premium prices for inferior materials from smaller producers.

Countries outside China’s sphere of influence find themselves at the mercy of Beijing’s foreign policy decisions. Australia and the United States have launched crash programs to restart domestic mining operations, but these efforts require years to become commercially viable while current supplies remain vulnerable to sudden cutoffs.

Rising costs driving urgent need for alternative sources

Rare earth mineral prices have increased by over 400% in the last five years, making previously affordable technologies prohibitively expensive. Neodymium, essential for high-performance magnets in electric vehicles, now costs more per kilogram than silver. Dysprosium prices have reached levels that force manufacturers to redesign entire product lines just to reduce consumption.

These price spikes ripple through every sector that depends on advanced technology. Smartphone manufacturers face margin compression as rare earth costs eat into profits. Wind energy projects get cancelled when turbine prices become economically unviable. Electric vehicle adoption slows as battery costs spiral upward.

Supply chain disruptions compound the problem. When a single processing facility in China shuts down for maintenance, global prices can jump 50% overnight. Companies maintain larger inventories than ever before, tying up billions in working capital just to ensure production continuity.

The economic pressure has sparked a gold rush mentality around space resource extraction. Private companies and government agencies alike recognize that lunar rare earth deposits could completely reshape global economics. The initial investment in space mining technology appears modest compared to the potential returns from breaking China’s stranglehold on these critical materials.

Traditional mining companies face an impossible choice: invest billions in environmentally destructive expansion projects that may never pay back, or pivot toward revolutionary space mining technology that could make terrestrial operations obsolete within decades.

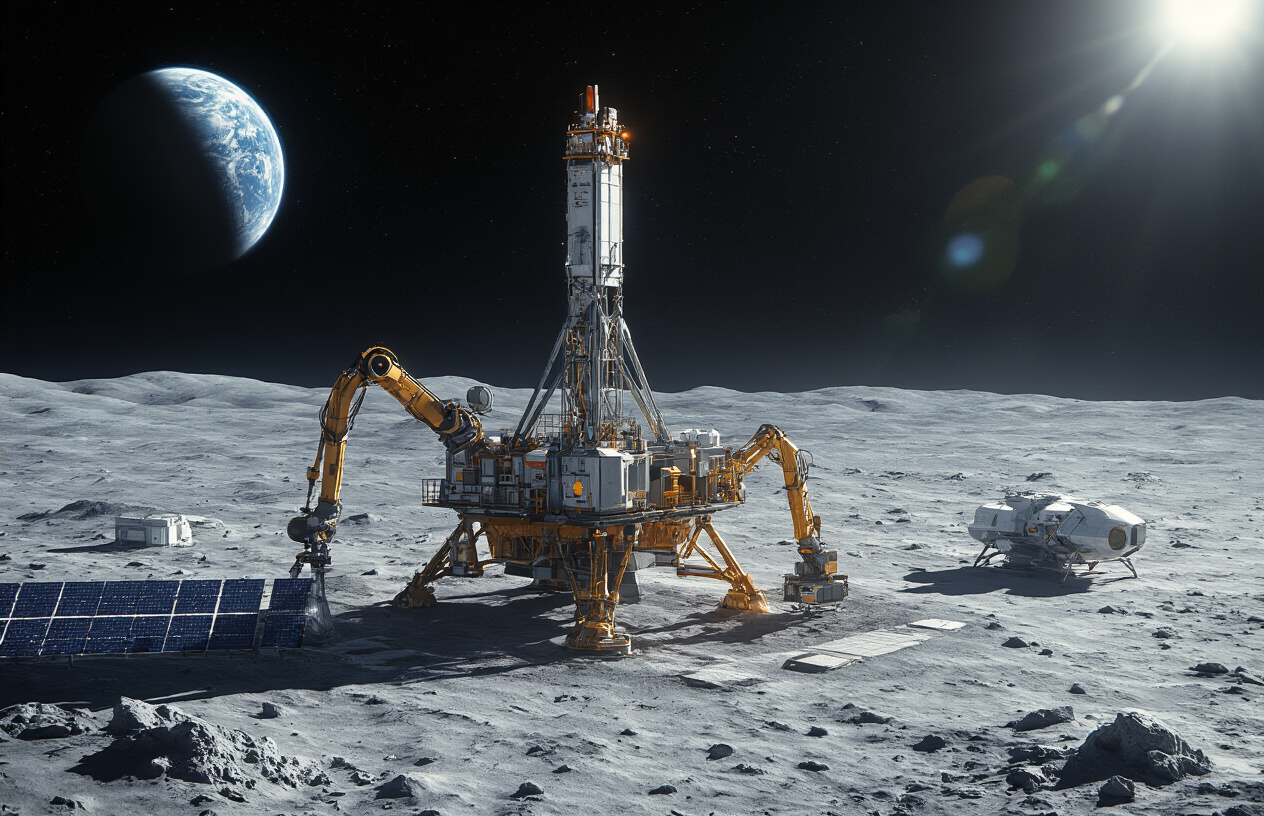

The Moon as the Ultimate Mining Frontier

Abundant rare earth deposits discovered through lunar exploration

Recent lunar missions have uncovered something extraordinary: the Moon contains massive quantities of rare earth elements that dwarf Earth’s remaining reserves. NASA’s Lunar Prospector and China’s Chang’e missions revealed that lunar soil holds concentrations of neodymium, europium, and yttrium that are significantly higher than terrestrial deposits. The lunar highlands contain an estimated 15-20 times more rare earth minerals per cubic meter compared to the richest Earth-based mines.

What makes these lunar rare earth deposits particularly exciting is their accessibility. Unlike Earth’s deep-buried reserves, many of these valuable materials sit near the Moon’s surface, deposited over billions of years through meteorite impacts. The South Pole-Aitken Basin alone contains enough rare earth elements to supply global demand for centuries. These deposits remain untouched by weathering or geological processes that typically complicate terrestrial extraction.

Helium-3 reserves offering revolutionary fusion energy potential

The Moon holds approximately 1 million tons of Helium-3, a rare isotope that could revolutionize energy production through clean fusion reactions. This precious resource, deposited by solar wind over billions of years, represents enough fuel to power Earth’s energy needs for thousands of years. A single cargo ship carrying 100 tons of lunar Helium-3 could generate the same energy output as all fossil fuels burned on Earth in an entire year.

Helium-3 fusion produces no radioactive waste and generates three times more energy than current fusion approaches. While terrestrial Helium-3 reserves amount to just 15 tons globally, the Moon’s regolith contains this isotope in concentrations of 10-15 parts per billion. Mining just the top few meters of lunar soil across relatively small areas could yield enough Helium-3 to meet humanity’s energy demands indefinitely.

Mining advantages in low gravity and vacuum environments

Lunar mining offers unique operational advantages that could transform space resource extraction efficiency. The Moon’s gravity is just 16% of Earth’s, meaning mining equipment requires less energy to move materials and can handle larger payloads with smaller machinery. Heavy excavation equipment that would be cumbersome on Earth becomes surprisingly agile in the lunar environment.

The vacuum of space eliminates many processing challenges. Without atmospheric interference, materials can be separated using electromagnetic methods that are impossible on Earth. Solar radiation provides consistent power for mining operations, while the absence of weather patterns means no storms, floods, or seasonal interruptions. Mining operations can run continuously for weeks without the logistical challenges that plague terrestrial mines.

Temperature extremes actually benefit certain extraction processes. The Moon’s cold regions can naturally freeze-concentrate valuable materials, while the hot zones can assist in thermal processing without requiring additional energy input.

Unlimited access without environmental destruction concerns

Space mining technology offers a compelling solution to Earth’s environmental crisis. Lunar mining produces zero impact on terrestrial ecosystems, eliminating the devastating effects of strip mining, toxic runoff, and habitat destruction that plague Earth-based rare earth extraction. No forests need clearing, no watersheds face contamination, and no communities require relocation for lunar mining operations.

The Moon lacks a biosphere to damage, making aggressive extraction methods environmentally neutral. Mining waste can be left on the lunar surface or even launched into space without ecological consequences. This guilt-free approach to resource extraction could supply Earth’s rare earth shortage solutions while preserving our planet’s remaining natural environments.

Regulatory frameworks for lunar mining remain simpler than terrestrial mining permits. The Outer Space Treaty provides basic guidelines, but doesn’t impose the complex environmental impact assessments, community consultations, and biodiversity protections required for Earth-based operations. This streamlined approach could accelerate project timelines from decades to years, making lunar rare earth deposits more economically attractive than traditional mining ventures.

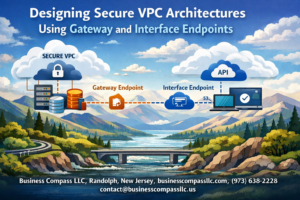

Breakthrough Technologies Making Lunar Mining Feasible

Advanced Robotic Systems for Autonomous Extraction Operations

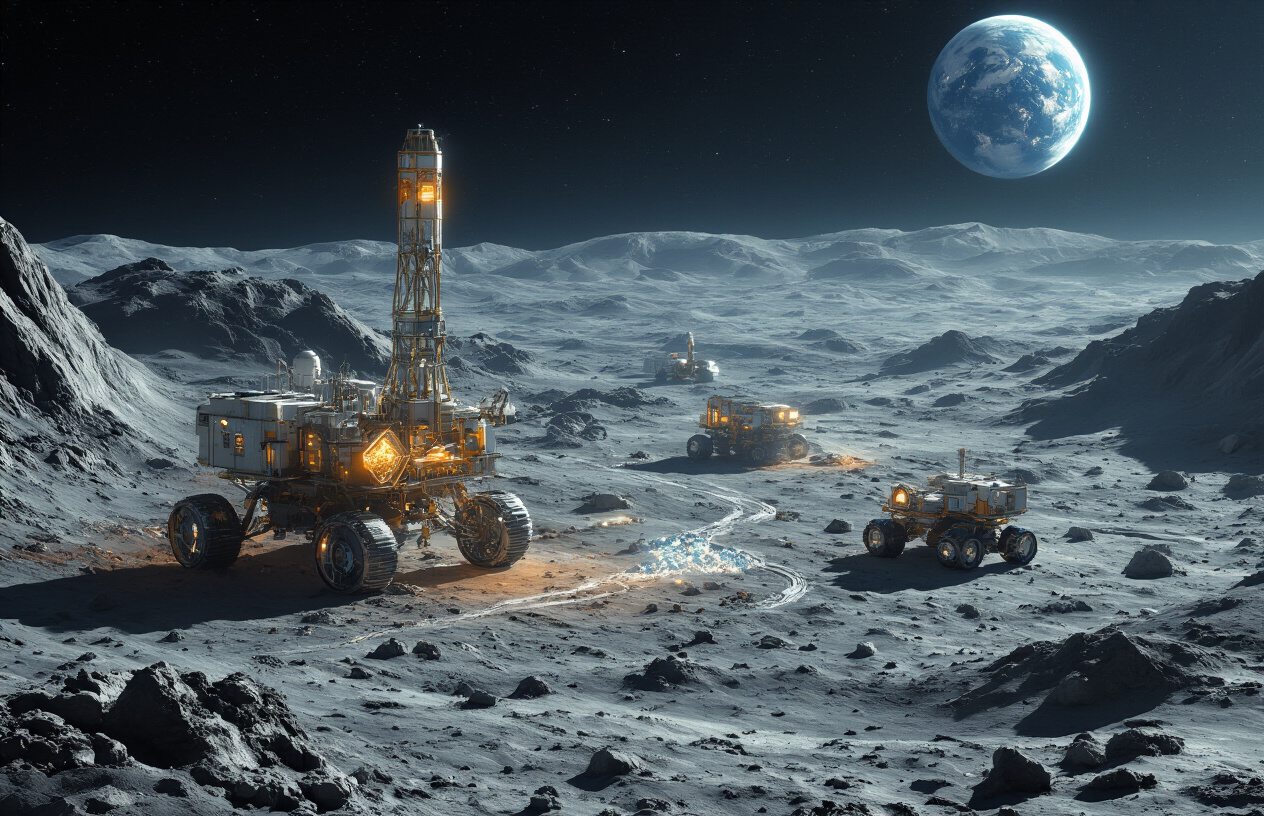

Space mining technology has reached a turning point with the development of sophisticated autonomous robots designed specifically for lunar operations. These machines can work continuously in the moon’s harsh environment without human intervention, operating through extreme temperature swings and radiation levels that would be lethal to astronauts.

The latest generation of lunar mining robots features AI-powered decision-making systems that adapt to unexpected geological conditions. They can identify the richest rare earth mineral deposits, adjust their extraction methods in real-time, and even perform self-maintenance when components wear out. Companies like NASA and SpaceX have successfully tested prototypes that can drill, excavate, and process materials with precision that rivals Earth-based mining equipment.

What makes these systems truly game-changing is their ability to learn and improve performance over time. Machine learning algorithms allow the robots to become more efficient with each operation, reducing waste and maximizing rare earth elements extraction. The robots communicate with each other through mesh networks, coordinating complex mining operations across multiple lunar sites simultaneously.

These autonomous systems also handle the dangerous aspects of moon mining feasibility that would put human crews at risk. They can work in areas with unstable terrain or high radiation levels, expanding the accessible mining areas far beyond what human-operated missions could achieve.

Cost-Effective Space Transportation Reducing Mission Expenses

Reusable rocket technology has dramatically changed the economics of lunar mining ventures. SpaceX’s Falcon Heavy and other next-generation launch systems have cut transportation costs by up to 90% compared to traditional single-use rockets. This cost reduction makes regular supply missions to lunar mining operations financially viable for the first time.

The development of space tugs and orbital transfer vehicles creates an efficient transportation network between Earth and the Moon. These specialized craft can ferry equipment and materials back and forth without requiring expensive launches from Earth’s surface for every mission. Fuel depots positioned at strategic points in space allow these vehicles to refuel during transit, extending their operational range and payload capacity.

Mass production of standardized spacecraft components has brought economies of scale to space transportation. Manufacturing rockets and mining equipment in larger quantities reduces per-unit costs significantly. Private companies are investing heavily in automated production facilities that can build spacecraft faster and cheaper than ever before.

Breakthrough propulsion technologies like ion drives and nuclear thermal rockets promise even greater cost savings. These advanced systems can carry heavier payloads to the Moon using less fuel, making large-scale rare earth minerals transportation economically attractive. The combination of reduced launch costs and improved cargo capacity creates a sustainable business model for space resource extraction.

In-Situ Resource Utilization Maximizing Operational Efficiency

The ability to create fuel, water, and building materials directly on the Moon eliminates the need to transport these heavy resources from Earth. In-situ resource utilization (ISRU) technology can extract oxygen from lunar rocks, harvest water from ice deposits at the Moon’s poles, and create rocket fuel using local materials. This self-sufficiency dramatically reduces mission costs and increases operational flexibility.

Lunar 3D printing technology enables construction of mining facilities using Moon dust and rocks as raw materials. These automated construction systems can build landing pads, storage facilities, and processing plants without shipping heavy construction materials across 240,000 miles of space. The printers work with regolith-based concrete that’s actually stronger than many Earth-based building materials.

Mobile refineries process rare earth elements on-site, concentrating valuable materials before shipping them back to Earth. This approach reduces transportation costs by eliminating the need to haul tons of raw ore across space. The refined materials are more valuable per pound, making the economics of lunar rare earth deposits much more attractive to investors.

ISRU systems also support long-term mining operations by creating spare parts and tools on demand. Advanced manufacturing equipment can produce replacement components for mining robots, reducing the need for expensive supply missions from Earth. This manufacturing capability extends mission lifespans and improves the overall return on investment for space mining ventures.

Energy production using lunar solar panels and nuclear reactors provides the power needed for large-scale mining operations. The Moon’s lack of atmosphere allows solar panels to operate at maximum efficiency, while small modular reactors can provide consistent power during the two-week lunar nights. This reliable energy supply supports continuous mining operations that maximize resource extraction rates.

Economic and Strategic Benefits of Space-Based Mining

Trillion-dollar market potential transforming global economy

Space-based mining represents one of the most lucrative opportunities in modern history, with analysts projecting a market worth several trillion dollars by 2050. The rare earth elements floating in space dwarf anything we’ve found on Earth. A single metallic asteroid could contain more platinum than has ever been mined on our planet, potentially worth hundreds of billions of dollars.

The economic ripple effects would be massive. Countries that master space mining economics first will control the supply chains for everything from smartphones to electric vehicles. China currently dominates rare earth mineral production, but lunar mining could completely reshape this dynamic. Nations investing in space resource extraction today are positioning themselves to become the new economic superpowers of tomorrow.

Traditional mining companies are already pivoting their strategies, recognizing that the future lies beyond our atmosphere. The space mining technology sector has attracted billions in venture capital, with companies racing to develop the infrastructure needed to extract and transport materials from space.

Energy independence through clean fusion power

The Moon holds the key to solving Earth’s energy crisis through Helium-3, a rare isotope that’s virtually nonexistent on our planet but abundant in lunar soil. This element could fuel clean fusion reactors without producing harmful radiation or long-lived radioactive waste.

Current estimates suggest the Moon contains enough Helium-3 to power Earth for thousands of years. A single cargo ship returning from lunar rare earth deposits could carry enough fusion fuel to meet a country’s energy needs for an entire year. This would eliminate dependence on fossil fuels and volatile oil markets.

Countries achieving energy independence through lunar resources would gain tremendous strategic advantages. They could offer cheaper, cleaner energy to attract manufacturing and technology companies, creating a competitive edge that traditional energy sources simply can’t match.

Technological leadership securing national competitive advantage

Nations leading in space mining will drive the next wave of technological innovation. The engineering challenges of extracting materials in zero gravity, harsh radiation, and extreme temperatures push the boundaries of robotics, artificial intelligence, and materials science.

These advances create spillover benefits across multiple industries. Robotic systems developed for asteroid mining improve manufacturing automation on Earth. Life support technologies designed for lunar operations enhance medical devices and environmental systems. Communication networks built for space operations strengthen terrestrial infrastructure.

The first countries to establish permanent lunar mining operations will set the technical standards that others must follow. This technological leadership translates into licensing opportunities, export advantages, and the ability to shape international space commerce regulations.

Job creation in emerging space industries

The space mining sector is already creating entirely new career paths and employment opportunities. Engineers, geologists, robotics specialists, and mission planners are finding high-paying jobs in this expanding field. Universities are launching specialized programs to train the workforce needed for space resource extraction.

Manufacturing jobs will multiply as companies build the rockets, rovers, processing equipment, and support infrastructure required for lunar operations. Traditional mining communities could transition into space mining hubs, leveraging existing expertise in resource extraction and processing.

Support industries are booming too. Space logistics companies, specialized insurance providers, and space-rated equipment manufacturers are hiring rapidly. The economic multiplier effect means every direct job in space mining creates several additional positions in supporting sectors.

| Job Category | Projected Growth | Salary Range |

|---|---|---|

| Space Mining Engineers | 300% by 2030 | $120K-250K |

| Lunar Operations Specialists | 500% by 2030 | $100K-200K |

| Space Robotics Technicians | 400% by 2030 | $80K-150K |

| Mission Control Analysts | 250% by 2030 | $90K-180K |

Overcoming Technical and Regulatory Hurdles

Engineering solutions for harsh lunar conditions

The Moon presents extreme challenges that push engineering to its limits. Temperatures swing wildly from 250°F during lunar day to -250°F at night, creating thermal stress that can crack even the toughest materials. Space mining technology must withstand these brutal conditions while maintaining precision operations for months or years.

Robotic mining systems need specialized thermal management systems, including radiative heat shields and internal heating elements powered by nuclear sources. The vacuum environment means traditional cooling methods won’t work, so engineers rely on heat pipes and phase-change materials to regulate temperatures. Lunar mining equipment also faces constant bombardment from micrometeorites and cosmic radiation, requiring hardened electronics and redundant systems.

Dust poses another major headache. Lunar regolith clings to everything due to electrostatic charges, potentially jamming moving parts and coating solar panels. Engineers are developing electrostatic dust shields and self-cleaning surfaces using ultrasonic vibrations. Advanced materials like carbon nanotubes and specialized ceramics resist dust accumulation while maintaining structural integrity.

Power generation remains critical since solar panels lose efficiency quickly from dust accumulation. Nuclear reactors designed for space applications offer reliable power, while fuel cells provide backup during equipment maintenance. Communication delays of 1.3 seconds each way to Earth mean mining robots need sophisticated AI systems for autonomous operation and real-time decision-making during emergencies.

International space law frameworks governing mining rights

Current space law creates a complex puzzle for space resource extraction operations. The 1967 Outer Space Treaty prohibits nations from claiming sovereignty over celestial bodies, but it doesn’t clearly address commercial mining rights. This legal gray area has sparked intense international debate about who can extract rare earth minerals from the Moon.

The United States took a bold step with the 2015 Commercial Space Launch Competitiveness Act, granting American companies property rights over resources they extract from asteroids and the Moon. Luxembourg followed with similar legislation, positioning itself as a European hub for space mining ventures. However, Russia and other nations argue these laws violate international agreements.

The Moon Agreement of 1984 attempted to establish international oversight of lunar resources, declaring them “the common heritage of mankind.” Only 18 countries signed this treaty, notably excluding major space powers like the US, Russia, and China. This creates competing legal frameworks that mining companies must navigate carefully.

Recent developments show promise for clearer regulations. The Artemis Accords, signed by over 20 nations, support the extraction and use of space resources while maintaining peaceful purposes. International bodies are working on comprehensive frameworks that balance commercial interests with global cooperation, recognizing that lunar rare earth deposits could transform Earth’s supply chains.

Safety protocols protecting astronauts and equipment

Human safety in lunar mining operations requires unprecedented protocols spanning everything from life support systems to emergency evacuations. Astronauts working near mining sites face unique hazards including equipment malfunctions in vacuum conditions, exposure to toxic dust, and limited rescue options.

Pressure suit technology has evolved dramatically for extended lunar surface operations. Modern suits incorporate self-healing materials that automatically seal small punctures, advanced air filtration systems that handle lunar dust, and integrated health monitoring sensors. Emergency oxygen supplies now last up to 8 hours, giving crews time to reach safety shelters during equipment failures.

Mining sites require multiple redundant safety systems. Pressurized emergency shelters positioned every 500 meters provide immediate refuge during dust storms or equipment accidents. These shelters contain independent life support systems, medical supplies, and communication equipment with direct Earth links. Automated safety systems constantly monitor air quality, radiation levels, and structural integrity of mining equipment.

Equipment protection protocols focus on preventing catastrophic failures that could endanger crews. All mining machinery includes fail-safe mechanisms that shut down operations if sensors detect anomalies. Regular maintenance schedules account for accelerated wear from lunar conditions, with key components replaced every 30 days rather than typical Earth-based intervals.

Emergency response procedures account for Earth’s communication delay, meaning ground control can’t provide real-time assistance. Crew training emphasizes autonomous decision-making and cross-training so any team member can operate essential life support and communication systems during emergencies.

Our planet’s rare earth minerals are running low, and the environmental costs of extraction keep climbing. Mining these essential materials on Earth damages ecosystems and creates toxic waste that communities have to live with for generations. The moon offers a clean slate – literally billions of tons of rare earth deposits sitting there untouched, waiting for us to figure out how to get them.

The technology is finally catching up to our ambitions. Automated mining robots, reusable rockets, and advanced extraction methods are moving from science fiction to real possibilities. Countries and companies that master lunar mining first will control the supply chains that power everything from smartphones to renewable energy systems. The race is on, and the winners will shape the next century of technological progress while leaving Earth’s fragile environment to heal.