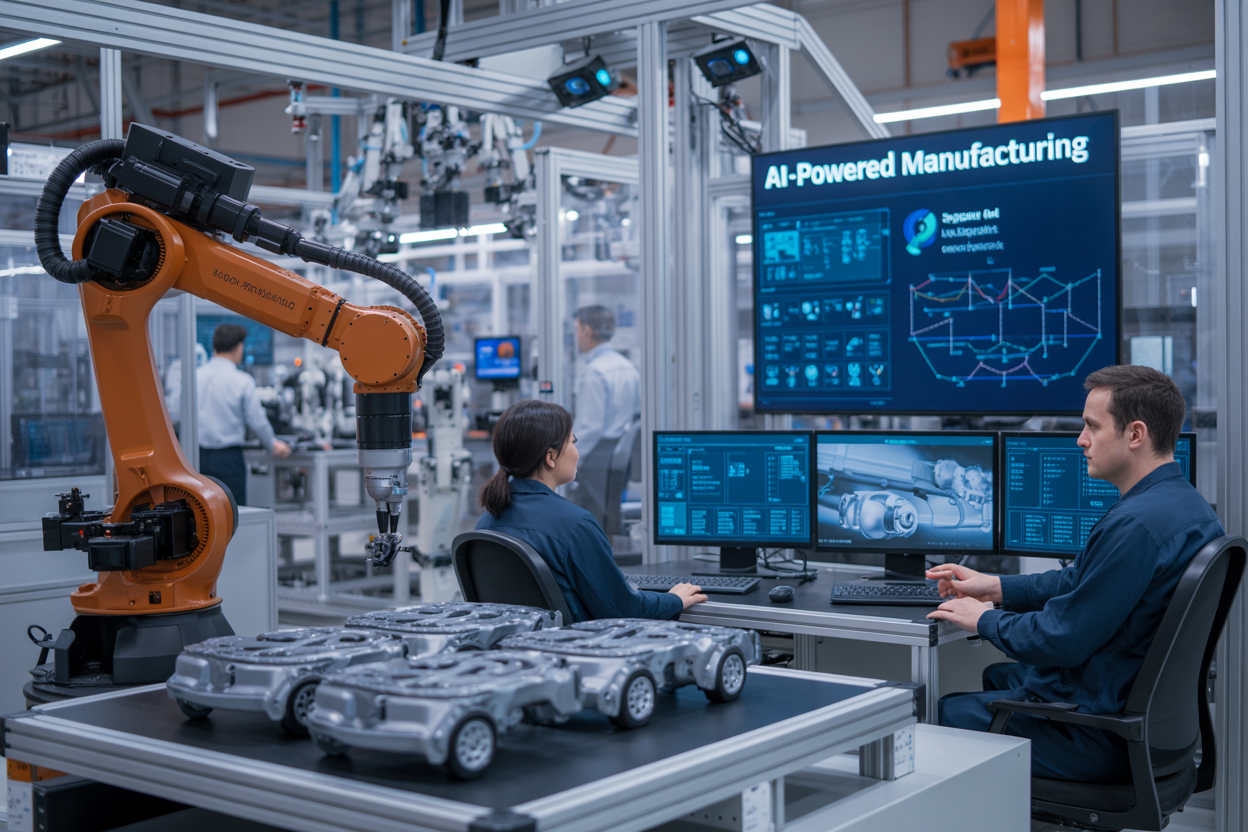

Manufacturing companies are racing to stay competitive, and AI in manufacturing is becoming the game-changer that separates industry leaders from those falling behind. This guide shows manufacturing executives, operations managers, and plant engineers exactly how to implement manufacturing AI solutions that deliver measurable results.

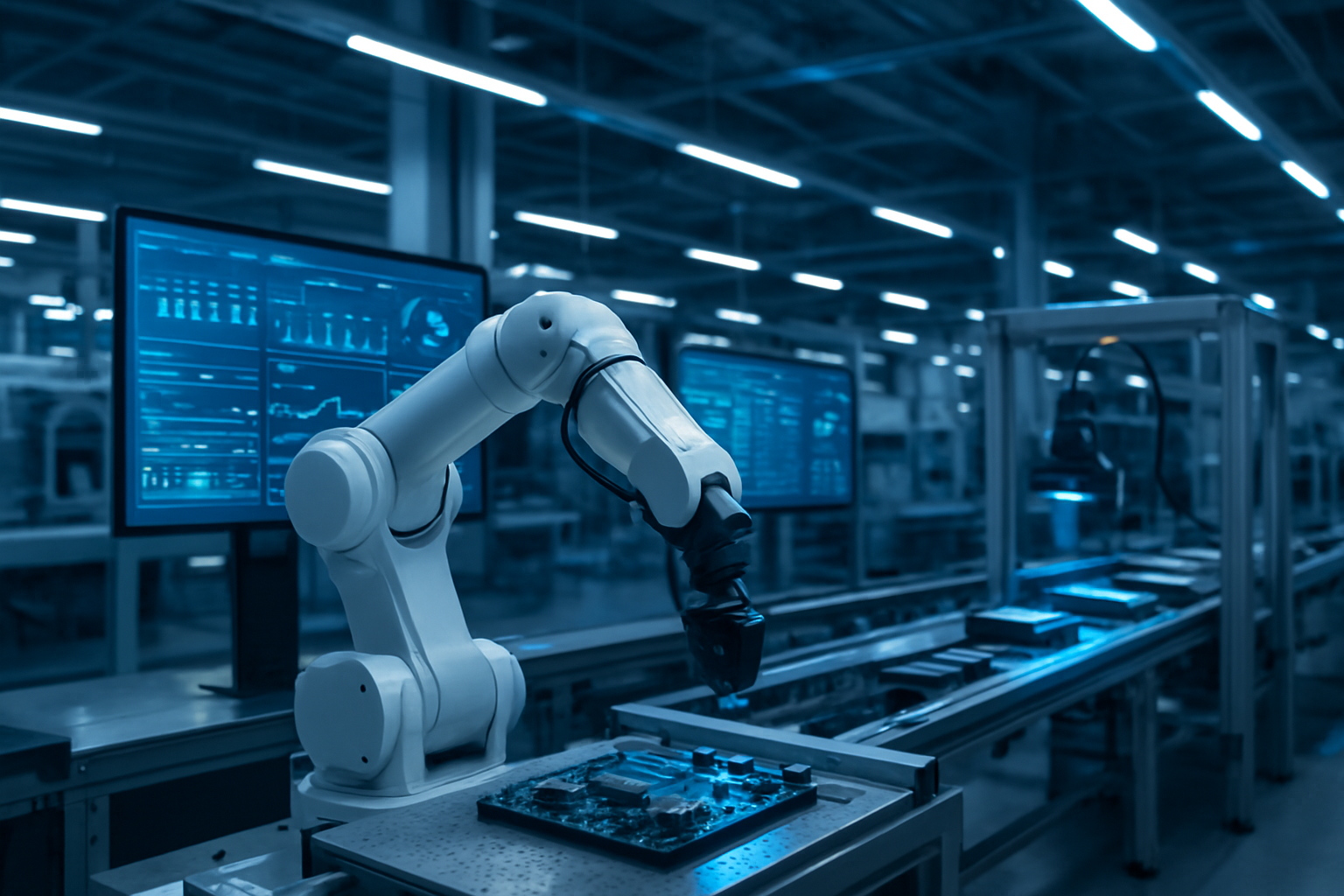

Smart manufacturers are already using AI quality control systems to catch defects before they reach customers, while predictive analytics supply chain tools help them avoid costly disruptions. Meanwhile, intelligent manufacturing robotics is reshaping production floors, making them safer and more efficient than ever before.

We’ll walk you through three critical areas where AI creates the biggest impact. First, you’ll discover how AI-powered inspection systems can transform your quality control processes and reduce defect rates by up to 90%. Next, we’ll explore how predictive analytics can optimize your supply chain operations, helping you anticipate problems before they happen. Finally, we’ll show you how intelligent manufacturing robotics integration can boost productivity while reducing labor costs and safety risks.

Transform Quality Control with AI-Powered Inspection Systems

Implement Computer Vision for Real-Time Defect Detection

Computer vision technology has become the backbone of modern AI quality control systems, enabling manufacturers to spot defects that human inspectors might miss. These systems use sophisticated algorithms to analyze thousands of products per minute, identifying surface scratches, dimensional inconsistencies, color variations, and assembly errors with remarkable precision.

The technology works by training neural networks on massive datasets of both perfect and defective products. Once deployed, cameras capture high-resolution images of each item as it moves through the production line. The AI system instantly compares these images against learned patterns, flagging any anomalies for immediate review or automatic rejection.

Leading manufacturers report catching defects as small as 0.1mm using AI-powered inspection systems. Companies like BMW and Samsung have integrated these solutions across their production lines, achieving detection rates that far exceed human capabilities while maintaining consistent performance around the clock.

Reduce Human Error Through Automated Quality Assessment

Human fatigue and inconsistency represent significant challenges in traditional quality control processes. Inspectors experience decreased accuracy after extended periods, leading to variations in acceptance standards and missed defects that can reach customers.

Automated quality assessment eliminates these human variables by applying identical inspection criteria to every single product. The systems don’t get tired, distracted, or influenced by external factors that affect human judgment. They maintain the same level of scrutiny whether it’s the first inspection of the day or the thousandth.

Manufacturing facilities using automated assessment report dramatic improvements in consistency. Workers can focus on higher-value tasks while AI handles repetitive inspection duties. The transition also creates opportunities for staff to develop new skills in system monitoring and data analysis.

Achieve 99% Accuracy in Product Inspection

Advanced AI quality control systems consistently deliver accuracy rates exceeding 99%, a benchmark that represents a significant leap forward from traditional inspection methods. This level of precision comes from the ability to process multiple data streams simultaneously, including visual, thermal, and dimensional measurements.

Machine learning algorithms continuously improve their detection capabilities by analyzing inspection results and learning from any missed defects. The systems build comprehensive databases of defect patterns, allowing them to recognize subtle variations that might indicate future quality issues.

Real-world implementations show impressive results:

| Industry | Traditional Accuracy | AI-Powered Accuracy | Improvement |

|---|---|---|---|

| Electronics | 85-90% | 99.2% | 10-14% |

| Automotive | 92-95% | 99.5% | 5-7% |

| Pharmaceuticals | 88-93% | 99.8% | 7-12% |

Cut Quality Control Costs by 40% with Smart Monitoring

Smart monitoring systems deliver substantial cost reductions by optimizing inspection processes and preventing defective products from reaching later production stages. Early detection saves materials, reduces rework expenses, and minimizes waste disposal costs.

The financial benefits extend beyond direct inspection savings. Automated systems operate continuously without breaks, overtime pay, or shift changes, reducing labor costs significantly. Maintenance requirements are predictable and often performed during scheduled downtime, avoiding unexpected production interruptions.

Energy efficiency represents another cost advantage. Modern AI inspection systems consume less power than traditional lighting-intensive manual inspection stations while providing superior results. Many manufacturers see return on investment within 12-18 months of implementation, with ongoing savings continuing for years.

Smart monitoring also enables predictive maintenance of inspection equipment, preventing costly breakdowns and extending system lifespan. The data collected helps optimize production parameters, reducing defect rates and improving overall manufacturing efficiency.

Optimize Supply Chain Operations Using Predictive AI Analytics

Forecast Demand with Machine Learning Algorithms

Predictive analytics supply chain management starts with accurate demand forecasting, and machine learning algorithms are game-changers in this space. These systems analyze historical sales data, seasonal patterns, market trends, and external factors like weather or economic indicators to predict future demand with remarkable precision.

Traditional forecasting methods often fall short when dealing with complex product portfolios and volatile markets. Machine learning models, however, can process massive datasets and identify subtle patterns that human analysts might miss. They continuously learn from new data, automatically adjusting predictions as market conditions change.

Key algorithms for demand forecasting include:

- Time series models (ARIMA, Prophet) for seasonal demand patterns

- Random Forest algorithms for handling multiple variables simultaneously

- Neural networks for complex, non-linear relationships

- Ensemble methods that combine multiple models for improved accuracy

Manufacturing companies using these AI-powered systems typically see 10-20% improvement in forecast accuracy compared to traditional methods. This translates directly into better production planning, reduced waste, and improved customer satisfaction.

Prevent Stockouts and Reduce Excess Inventory

Smart inventory optimization balances the costly trade-off between carrying too much stock and running out of critical materials. AI in manufacturing transforms this challenge by creating dynamic inventory models that respond to real-time demand signals and supply constraints.

Machine learning algorithms analyze consumption patterns, lead times, supplier reliability, and seasonal variations to determine optimal reorder points and safety stock levels. These systems automatically adjust parameters as conditions change, preventing the manual guesswork that often leads to inventory problems.

AI-driven inventory management delivers:

| Benefit | Typical Improvement |

|---|---|

| Inventory carrying costs | 15-25% reduction |

| Stockout incidents | 30-50% decrease |

| Working capital efficiency | 10-20% improvement |

| Demand forecast accuracy | 15-30% increase |

Advanced systems also incorporate external data like supplier disruptions, transportation delays, or market volatility to proactively adjust inventory levels. This predictive approach helps manufacturers avoid supply chain disruptions before they impact production.

Enhance Supplier Performance Through Data-Driven Insights

Manufacturing AI solutions excel at transforming supplier relationships through comprehensive performance analytics. Instead of relying on periodic reviews or manual scorecards, AI systems continuously monitor supplier performance across multiple dimensions.

These platforms aggregate data from purchase orders, delivery confirmations, quality reports, and financial metrics to create real-time supplier dashboards. Machine learning algorithms identify trends, flag potential issues, and even predict which suppliers might face difficulties in meeting future commitments.

Data-driven supplier insights include:

- Delivery performance analysis tracking on-time delivery rates and lead time variability

- Quality metrics monitoring defect rates, return frequencies, and compliance scores

- Risk assessment modeling financial stability, geographic vulnerabilities, and capacity constraints

- Cost optimization opportunities identifying alternative sources and negotiation leverage

Smart manufacturing technology enables proactive supplier management by alerting procurement teams to potential issues weeks or months in advance. This early warning system allows manufacturers to work with suppliers on improvement plans or identify alternative sources before problems affect production schedules.

The most sophisticated systems use natural language processing to analyze supplier communications, contract terms, and market intelligence, providing a 360-degree view of supplier relationships that drives strategic decision-making.

Revolutionize Manufacturing with Intelligent Robotics Integration

Deploy Collaborative Robots for Enhanced Worker Safety

Collaborative robots, or cobots, are changing how humans and machines work together on the factory floor. Unlike traditional industrial robots that operate behind safety cages, cobots are designed to work alongside human operators safely. These intelligent manufacturing robotics systems come equipped with advanced sensors that detect human presence and automatically adjust their speed or stop completely when someone gets too close.

Manufacturing companies are seeing dramatic improvements in workplace safety metrics after deploying cobots. These robots handle dangerous tasks like welding, chemical handling, and heavy lifting while workers focus on quality checks and complex problem-solving. The built-in safety features include force sensors that detect unexpected contact, vision systems that track human movement, and machine learning algorithms that adapt to changing work environments.

Modern cobots learn from their human counterparts, making them ideal for tasks requiring both precision and adaptability. They can be programmed through simple demonstrations rather than complex coding, allowing floor operators to teach them new tasks quickly. This collaborative approach reduces workplace injuries by up to 40% while maintaining high productivity levels.

Increase Production Speed with AI-Guided Automation

AI-powered automation systems are transforming production speeds across manufacturing facilities. These systems use real-time data analysis to optimize robot movements, predict bottlenecks, and adjust production parameters automatically. Manufacturing automation AI can process thousands of variables simultaneously, making split-second decisions that human operators couldn’t match.

Machine learning algorithms continuously analyze production patterns to identify efficiency improvements. They track everything from robot arm movements to material flow rates, finding opportunities to shave milliseconds off cycle times. These micro-optimizations add up to significant productivity gains – many manufacturers report 25-35% increases in output after implementing AI-guided systems.

The technology also enables dynamic load balancing across production lines. When one robot experiences a slowdown, the AI system automatically redistributs tasks to maintain overall throughput. This intelligent coordination prevents cascading delays and keeps production running smoothly even when individual components face issues.

Adapt to Product Variations Through Self-Learning Systems

Modern manufacturing faces increasing demand for customization and shorter product lifecycles. Self-learning robotic systems excel in these challenging environments by adapting to new product variations without extensive reprogramming. These smart manufacturing technology solutions use computer vision and machine learning to recognize different product types and automatically adjust their operations.

The robots learn from each production run, building a knowledge base of successful handling techniques for various products. When encountering a new variation, they apply this learned experience to determine optimal gripping points, movement paths, and processing parameters. This adaptability eliminates the weeks of downtime traditionally required for production line changeovers.

Pattern recognition capabilities allow robots to handle products with slight dimensional variations or cosmetic differences. They can adjust their approach based on real-time visual feedback, ensuring consistent quality regardless of product variations. Some systems can even detect and compensate for material property changes, such as flexibility or surface texture differences.

Minimize Downtime with Predictive Maintenance Robots

Predictive maintenance robots are revolutionizing how manufacturers approach equipment reliability. These specialized robots continuously monitor production machinery using thermal imaging, vibration analysis, and acoustic monitoring to detect early signs of wear or failure. By catching problems before they cause breakdowns, manufacturers can reduce unplanned downtime by up to 50%.

The robots patrol production floors autonomously, equipped with sophisticated sensors that can detect temperature anomalies, unusual vibrations, or abnormal sounds that indicate impending equipment failure. AI algorithms analyze this data to predict when maintenance will be needed, allowing teams to schedule repairs during planned downtime rather than emergency stops.

Machine learning models become more accurate over time as they accumulate data about equipment behavior patterns. They learn to distinguish between normal operational variations and genuine warning signs, reducing false alarms while catching real issues early. Some systems can even order replacement parts automatically when they detect components approaching their wear limits.

Scale Operations Efficiently with Flexible Robotic Solutions

Flexible robotic solutions enable manufacturers to scale operations up or down quickly without massive capital investments. Modular robot systems can be reconfigured for different tasks, moved between production lines, or combined to handle larger workloads. This flexibility is crucial for manufacturers dealing with fluctuating demand or seasonal variations.

Cloud-connected robotics platforms allow manufacturers to deploy new capabilities rapidly across multiple facilities. Software updates can add new functions or improve existing ones without hardware changes. This approach reduces the total cost of ownership while providing access to the latest AI capabilities as they become available.

Rental and robot-as-a-service models are making advanced automation accessible to smaller manufacturers. These flexible deployment options allow companies to test robotic solutions before committing to purchases, scale their automation gradually as business grows, and access cutting-edge technology without large upfront investments. The subscription-based approach includes ongoing support, updates, and maintenance, making it easier for manufacturers to focus on production rather than robot management.

Leverage Generative AI for Design and Process Innovation

Generate Optimized Product Designs in Minutes

Generative AI manufacturing solutions are transforming how companies approach product development by creating optimized designs at unprecedented speeds. Traditional design cycles that once took weeks or months can now be compressed into minutes using AI-powered design tools. These systems analyze thousands of design parameters simultaneously, considering factors like material constraints, manufacturing limitations, and performance requirements to generate multiple design alternatives.

AI design platforms use advanced algorithms to explore design spaces that human engineers might never consider. They can automatically optimize for weight reduction, stress distribution, material usage, and manufacturing cost while maintaining structural integrity. For example, automotive manufacturers use generative AI to create lightweight components that maintain strength requirements, reducing vehicle weight and improving fuel efficiency.

The technology excels at topology optimization, where AI algorithms remove unnecessary material while preserving essential structural elements. This process creates organic-looking designs that are both functional and material-efficient. Aerospace companies leverage these capabilities to design aircraft components that are 30-40% lighter than traditionally designed parts while meeting stringent safety standards.

Create Custom Manufacturing Processes Automatically

Smart manufacturing technology now enables automatic generation of custom manufacturing processes tailored to specific products and production requirements. AI systems analyze product specifications, available equipment, and production constraints to develop optimized manufacturing workflows without human intervention.

These intelligent systems consider multiple variables including machine capabilities, tooling requirements, cycle times, and quality parameters to create comprehensive process plans. The AI evaluates different manufacturing approaches and selects the most efficient combination of operations, sequencing, and resource allocation.

Process automation extends beyond simple task sequencing to include dynamic adjustments based on real-time conditions. AI monitors production data and automatically modifies processes to maintain quality standards and optimize throughput. This adaptive capability allows manufacturers to respond quickly to changing demands or unexpected issues without manual intervention.

Manufacturing AI solutions can also predict potential bottlenecks and suggest alternative process routes before problems occur. This proactive approach minimizes downtime and ensures consistent production flow across complex manufacturing environments.

Accelerate Prototyping with AI-Generated Solutions

AI-powered prototyping dramatically reduces the time from concept to physical prototype by automating design validation and optimization processes. Instead of multiple iteration cycles, AI can simulate thousands of design variations and identify the most promising candidates for physical testing.

Virtual prototyping using AI eliminates many traditional trial-and-error approaches. The technology predicts how designs will perform under various conditions, identifying potential failures before expensive prototypes are built. This capability is particularly valuable in industries like medical devices or automotive, where prototype costs are substantial.

AI also optimizes prototyping processes by selecting appropriate materials, manufacturing methods, and testing procedures based on design requirements. The system can recommend rapid prototyping techniques like 3D printing parameters or suggest conventional manufacturing approaches depending on the prototype’s intended use.

Integration with digital twins enables continuous refinement of prototypes based on real-world performance data. As physical prototypes undergo testing, AI incorporates the results into future design iterations, creating a feedback loop that continuously improves the prototyping process. This approach significantly shortens development cycles while improving final product quality.

Implement AI Solutions Successfully in Your Manufacturing Environment

Choose the Right AI Technologies for Your Specific Needs

Starting your AI journey requires a strategic approach to technology selection. Begin by assessing your current manufacturing challenges and identifying where artificial intelligence can deliver the biggest impact. Manufacturing AI solutions work best when they address specific pain points like defect detection, equipment downtime, or inventory optimization.

Evaluate your existing infrastructure before committing to any AI-powered inspection systems or smart manufacturing technology. Legacy equipment might need upgrades or integration middleware to work with modern AI platforms. Consider cloud-based solutions for scalability, especially if you’re planning to expand across multiple facilities.

Budget constraints often shape technology choices, but don’t let initial costs overshadow long-term value. Industrial AI implementation requires different investment levels depending on complexity. Simple predictive analytics supply chain tools might cost thousands, while comprehensive intelligent manufacturing robotics systems could require millions.

| AI Technology Type | Best For | Initial Investment | Implementation Time |

|---|---|---|---|

| Computer Vision | Quality control, safety monitoring | $50K-$200K | 3-6 months |

| Predictive Analytics | Equipment maintenance, demand forecasting | $25K-$100K | 2-4 months |

| Robotics Integration | Assembly, packaging, material handling | $200K-$2M | 6-18 months |

| Generative AI | Design optimization, process improvement | $10K-$75K | 1-3 months |

Work with vendors who understand manufacturing environments. Your chosen AI partner should offer proof-of-concept trials, demonstrate ROI projections, and provide clear implementation roadmaps.

Train Your Workforce for AI Integration

Successful AI adoption depends heavily on workforce readiness. Your team needs both technical knowledge and confidence to work alongside intelligent systems. Start training programs early, ideally before AI installation begins.

Focus on hands-on learning rather than theoretical concepts. Operators need to understand how AI systems make decisions, when to trust automated recommendations, and how to intervene when necessary. Manufacturing automation AI changes daily workflows, so practical training sessions work better than classroom lectures.

Create different training tracks for various roles:

- Operators: System monitoring, basic troubleshooting, safety protocols

- Technicians: Advanced diagnostics, system maintenance, data interpretation

- Engineers: Algorithm tuning, integration management, performance optimization

- Managers: ROI analysis, strategic planning, change management

Partner with AI vendors for specialized training programs. Many providers offer certification courses designed specifically for manufacturing environments. These programs often include real-world scenarios and hands-on experience with actual equipment.

Establish internal AI champions who can mentor other employees and troubleshoot common issues. These subject matter experts become valuable resources as you scale AI adoption across multiple production lines.

Address concerns about job displacement directly. Emphasize how AI enhances human capabilities rather than replacing workers. Share success stories from other manufacturers who’ve improved both productivity and employee satisfaction through smart manufacturing technology.

Measure ROI and Performance Improvements

Tracking AI performance requires both financial and operational metrics. Set baseline measurements before implementation to accurately assess improvements. Focus on key performance indicators that align with your original goals for AI adoption.

Common ROI metrics include:

- Quality improvements: Defect reduction rates, customer complaints, warranty claims

- Efficiency gains: Production throughput, cycle time reduction, resource utilization

- Cost savings: Labor reduction, material waste, energy consumption, maintenance costs

- Revenue impact: Increased capacity, faster time-to-market, premium pricing for quality

Manufacturing AI solutions often deliver benefits across multiple areas simultaneously. AI quality control systems might reduce defects while increasing production speed. Predictive analytics supply chain tools can lower inventory costs while improving delivery performance.

Calculate total cost of ownership including software licensing, hardware upgrades, training expenses, and ongoing maintenance. Many organizations underestimate implementation costs, leading to inflated ROI projections. Factor in productivity losses during the learning curve period.

Use data visualization dashboards to track performance in real-time. These tools help identify trends, spot anomalies, and make data-driven decisions about system adjustments. Share results with stakeholders regularly to maintain support for AI initiatives.

Document both quantitative results and qualitative benefits like improved employee satisfaction or enhanced safety conditions. These soft benefits often justify continued investment even when financial returns take longer to materialize.

Scale AI Adoption Across Multiple Production Lines

Scaling requires systematic planning rather than simply copying successful implementations. Each production line has unique characteristics that might demand customized AI approaches. Start with pilot programs on representative lines before committing to facility-wide deployment.

Develop standardized implementation frameworks that can adapt to different production environments. This includes common data formats, integration protocols, and training procedures. Standardization reduces costs and accelerates deployment timelines for subsequent installations.

Create cross-functional teams responsible for scaling efforts. Include representatives from IT, operations, maintenance, and quality assurance. These teams ensure that AI solutions integrate smoothly with existing processes and systems across all production areas.

Plan for infrastructure requirements early. Scaling intelligent manufacturing robotics or AI-powered inspection systems often requires network upgrades, additional computing power, or enhanced data storage capabilities. Budget for these infrastructure improvements in your scaling timeline.

Consider phased rollouts that minimize operational disruptions. Implement AI systems during scheduled maintenance windows or production breaks when possible. Have rollback plans ready in case systems don’t perform as expected initially.

Monitor performance consistency across different lines and locations. AI models trained on data from one production line might need adjustment when applied elsewhere. Machine learning algorithms often require retraining with local data to maintain accuracy and effectiveness.

AI and generative AI are reshaping how manufacturers approach quality control, supply chain management, and robotics. From automated inspection systems that catch defects faster than human eyes to predictive analytics that prevent supply chain disruptions before they happen, these technologies offer real solutions to everyday manufacturing challenges. Smart robotics integration and generative AI design tools are taking efficiency and innovation to new levels that seemed impossible just a few years ago.

The key to success lies in taking a strategic approach to implementation rather than jumping in without a plan. Start with pilot programs in areas where you can see quick wins, build your team’s AI knowledge, and scale up gradually. The manufacturers who embrace these tools today while learning how to use them effectively will be the ones setting industry standards tomorrow. Your competition is already exploring these possibilities – the question isn’t whether to adopt AI, but how quickly you can make it work for your operations.